Management > QUESTIONS & ANSWERS > APM Quizes: Week 2 to Week 10. The most frequently tested questions. (All)

APM Quizes: Week 2 to Week 10. The most frequently tested questions.

Document Content and Description Below

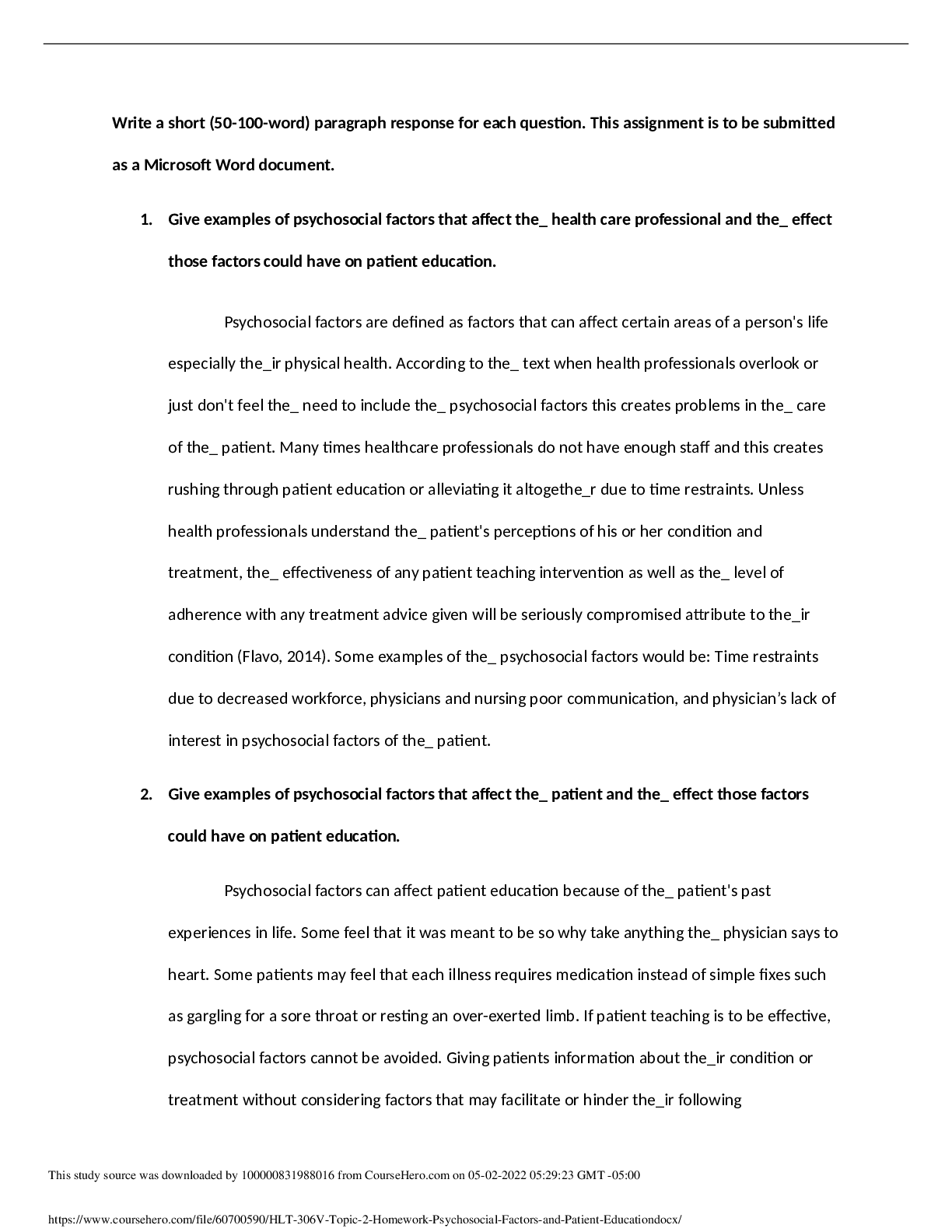

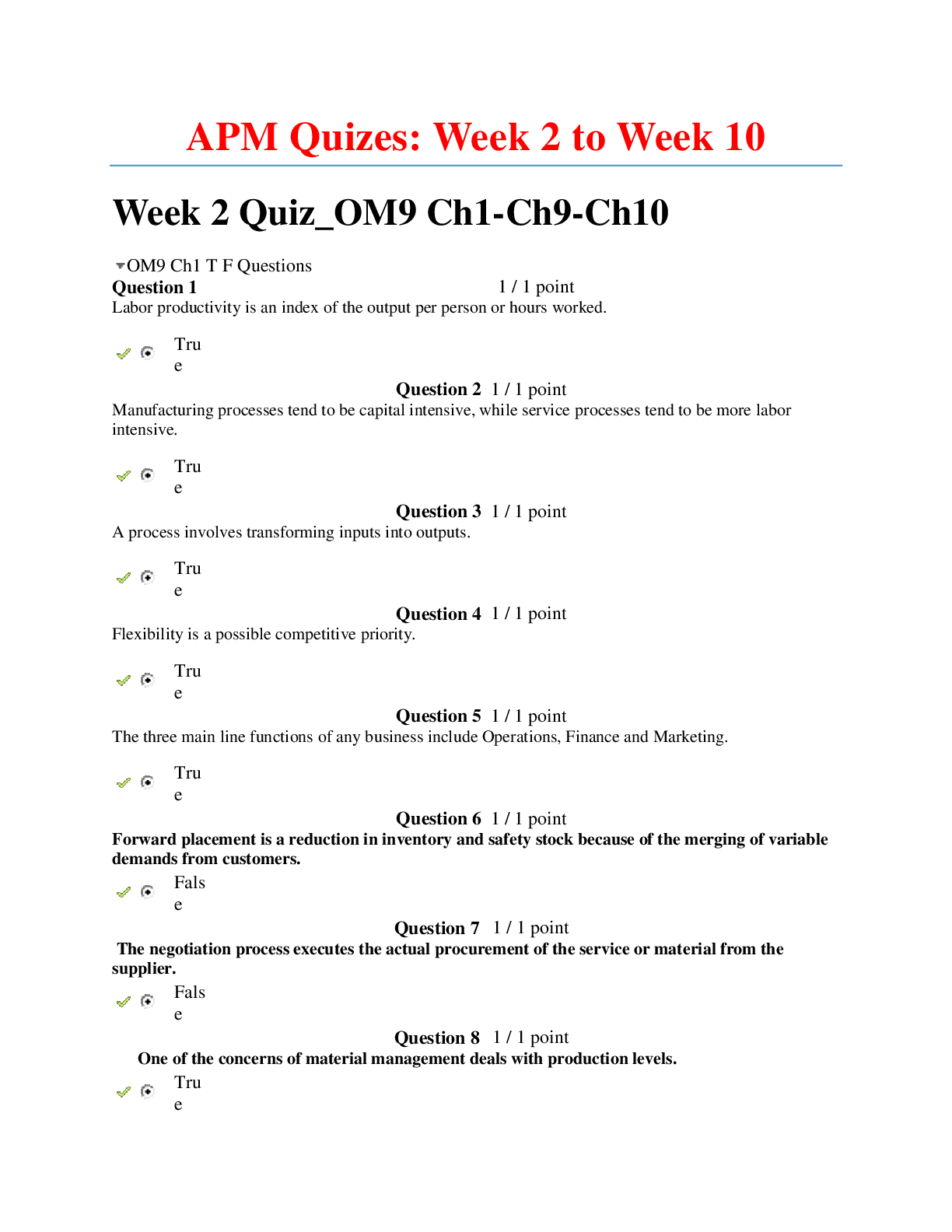

APM Quizes: Week 2 to Week 10 Week 2 Quiz_OM9 Ch1-Ch9-Ch10 OM9 Ch1 T F Questions Question 1 1 / 1 point Labor productivity is an index of the output per person or hours worked. Question... 2 1 / 1 point Manufacturing processes tend to be capital intensive, while service processes tend to be more labor intensive. Question 3 1 / 1 point A process involves transforming inputs into outputs. Question 4 1 / 1 point Flexibility is a possible competitive priority. Question 5 1 / 1 point The three main line functions of any business include Operations, Finance and Marketing. Question 6 1 / 1 point Forward placement is a reduction in inventory and safety stock because of the merging of variable demands from customers. Question 7 1 / 1 point The negotiation process executes the actual procurement of the service or material from the supplier. Question 8 1 / 1 point One of the concerns of material management deals with production levels. Question 9 1 / 1 point It is better to keep the order fulfillment process in-house than to use a virtual supply chain when sales volumes are high. Question 10 1 / 1 point Green purchasing involves identifying, assessing, and managing the flow of environmental waste and finding ways to reduce it and minimize its impact on the environment. Question 11 1 / 1 point When high service or product variety is important, the traditional order fulfillment method is preferable to a virtual supply-chain approach. Question 12 1 / 1 point The competitive orientation to supplier relations is that the buyer and supplier are partners. Question 13 1 / 1 point Dell, a wildly successful computer company, can configure exactly the computer you want thanks to their mass production system. Question 14 1 / 1 point In presourcing, suppliers are selected early in the concept-development stage. Question 15 1 / 1 point Value analysis is a systematic effort to reduce the cost or improve the performance of products or services. Question 16 2 / 2 points Which of the following statements is best? Operations management can be made more effective by: a. focusing on aspects of operations that are directly related to production. b. coordinating operations with other functional areas that impact operations. c. making production early enough so that stockouts do not occur. d. coordinating all activities related to operations directly or indirectly, both within and outside the organization. Question 17 2 / 2 points The process that includes the activities required to produce and deliver the service or product to the customer is called the: a. customer relationship process. b. new service development process. c. order fulfillment process. d. supplier relationship process. Question 18 2 / 2 points A company’s ability to support varying rates of production is best described as: a. volume flexibility. b. variety. c. consistent quality. d. development speed. Question 19 2 / 2 points Operations management is part of a production system that can be described in the following manner: Organization: inputsprocessesoutputs.Which one of the following correctly describes a production system? a. Airline: pilotsplanestransportationb b. Bank: tellerscomputer equipmentdeposits c. Furniture manufacturer: woodsandingchair d. Telephone company: satellitescablescommunication Question 20 2 / 2 points Which one of the following statements regarding operations management is ? a. Inputs to a production system include capital and materials, but not human resources. b. Operations management deals only with manufacturing organizations because service organizations do not have tangible outputs. c. Typical inputs to a production system are processes and consumer goods. d. Customer participation and information on performance are two special types of inputs to a production system. Question 21 2 / 2 points The basic purpose of supply chain management is to: a) link your customers together so that the flow of materials remains under control. b) synchronize the operations of all suppliers with those of purchasing, production, distribution, and customers. c) reduce the inventory by proper selection of customers and transportation modes. d) create an exclusive set of suppliers who will not supply your competitors. Question 22 2 / 2 points One source of disruption caused by the internal supply chain is: a) forecast error. b) underfilled shipments. c) volume changes. d) late deliveries. Question 23 2 / 2 points The supply chain for a service provider must account for retail stores, delivery centers, points-of-sale equipment, and employees. These elements of the service package are part of the: a) supporting facilities. b) facilitating goods. c) explicit services. d) implicit services. Question 24 2 / 2 points The bullwhip effect is characterized by: a) ordering patterns that experience increasing variance as you proceed downstream in the chain. b) ordering patterns that experience increasing variance as you proceed upstream in the chain. c) purchasing patterns that experience increasing variance downstream in the chain. d) purchasing patterns that experience decreasing variance as you proceed upstream in the chain. Question 25 2 / 2 points Possible causes of disruption due to internal supply chain problems are: a) late deliveries. b) machine breakdowns or inexperienced workers. c) product and service mix changes. d) underfilled shipments. Wk 2 Key Terms to Know Question 26 1 / 1 point The process of involving suppliers early in the product design activity and drawing on their expertise, insights, and knowledge to generate better designs in less time and designs that are easier to manufacture with high quality. See: . Question 27 1 / 1 point The design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand, and measuring performance globally. Question 28 1 / 1 point The determination of how to structure a supply chain--decisions include the selection of partners, the location and capacity of warehouse and production facilities, the products, the modes of transportation, and supporting information systems. Question 29 1 / 1 point A comprehensive approach to managing an enterprise’s interactions with the organizations that supply the goods and services the enterprise uses. The goal of it is to streamline and make more effective the processes between an enterprise and its suppliers. It is often associated with automating procure-to-pay business processes, evaluating supplier performance, and exchanging information with suppliers. An e-procurement system often comes under the umbrella of a supplier relationship management family of applications Question 30 1 / 1 point An extreme change in the supply position upstream in a supply chain generated by a small change in demand downstream in the supply chain. Inventory can quickly move from being backordered to being excess. This is caused by the serial nature of communicating orders up the chain with the inherent transportation delays of moving product down the chain. This effect can be eliminated by synchronizing the supply chain. Question 1 1 / 1 point Regression equations with a coefficient of determination close to zero are extremely accurate because they have little forecast error. Question 2 1 / 1 point Market research is a systematic approach to determine consumer interest by gaining consensus from a group of experts while maintaining their anonymity. Question 3 1 / 1 point Judgment methods of forecasting are quantitative methods that use historical data on independent variables to predict demand. Question 4 1 / 1 point Time-series forecasts require information about only the dependent variable. Question 5 1 / 1 point The causal method of forecasting uses historical data on dependent variables such as promotional campaigns and economic conditions to predict the demand of independent variables such as sales volume. Question 6 1 / 1 point Aggregating products or services together generally decreases the forecast accuracy. Question 7 0 / 1 point A forecast of sales revenue has little value. Question 8 1 / 1 point A linear regression model results in the equation Y=15-23X. If the coefficient of determination is a perfect 1.0, the correlation coefficient must be -1. Question 9 1 / 1 point Time-series analysis is a statistical approach that relies heavily on historical demand data to project the future size of demand. Question 10 1 / 1 point Some analysts prefer to use a holdout set as the final test of a forecasting procedure. Question 11 1 / 1 point Technological forecasting is an application of executive opinion in light of the difficulties in keeping abreast of the latest advances in technology. Question 12 1 / 1 point Focus forecasting selects the best forecast from a group of forecasts generated by individual techniques. Question 13 1 / 1 point An exponential smoothing model with an alpha equal to 1.00 is the same as a naïve forecasting model. Question 14 1 / 1 point One of the basic time series patterns is random. Question 15 1 / 1 point Forecasts almost always contain errors. Question 16 1 / 1 point One of the basic time series patterns is trend. Question 17 1 / 1 point Salesforce estimates are extremely useful for technological forecasting. Question 18 1 / 1 point The repeated observations of demand for a product or service in their order of occurrence form a pattern known as a time series. Question 19 1 / 1 point The exponential smoothing method is a sophisticated, weighted, moving-average method. 7810 week 3 ch13 MC questions Question 20 2 / 2 points The electricity bill at Padco was driven solely by the lights throughout the office; everything else was driven by alternative energy sources. The office was open roughly 8 hours a day, five days a week and the cleaning crew spent about the same amount of time in the offices each week night. The kilowatt hour usage for the office was best described as a: a) horizontal demand pattern. b) random demand pattern. c) seasonal demand pattern. d) cyclical demand pattern. Question 21 2 / 2 points When forecasting total demand for all their services or products, few companies err by more than: a) one percent. b) ten percent. c) five percent. d) twenty percent. Question 22 2 / 2 points Which one of the following statements about forecasting is ? a) To achieve the objective of developing a useful forecast from the information at hand, the forecaster must select the appropriate technique. This choice sometimes involves a trade-off between forecast accuracy and cost. b) Three general types of forecasting techniques are used for demand forecasting: time-series analysis, causal methods, and judgment methods. c) Time series express the relationship between the factor to be forecast and related factors such as promotional campaigns, economic conditions, and competitor actions. d) A time series is a list of repeated observations of a phenomenon, such as demand, arranged in the order in which they actually occurred. Question 23 2 / 2 points Which one of the following statements about forecasting is ? a) The five basic patterns of demand are the horizontal, trend, seasonal, cyclical, and the subjective judgment of forecasters. b) Judgment methods are designed particularly for situations in which historical data are lacking. c) Casual methods are used when historical data are available and the relationship between the factor to be forecast and other external and internal factors cannot be identified. d) Focused forecasting is a technique that focuses on one particular component of demand and develops a forecast from it. Question 24 2 / 2 points Short term is the correct time horizon for which of the following decisions? a) Master production planning. b) Capacity planning c) Process management d) Facility location Question 25 2 / 2 points There are historically three 32-month periods of generally rising prices in the stock market for every one 9-month period of falling prices. This observation leads you to conclude that the stock market exhibits a: a) random pattern. b) trend pattern c) seasonal pattern. d) cyclical pattern. Question 26 2 / 2 points One aspect of demand that makes every forecast inaccurate is: a) trend variation. b) random variation. c) cyclical variation. d) seasonal variation. Question 27 2 / 2 points Which one of the following factors affecting demand for goods and services is an external factor? a) Product design b) Consumer tastes c) Price and advertising promotions d) Packaging design Key Terms to Know Week 3 Question 28 1 / 1 point A qualitative forecasting technique where the opinions of experts are combined in a series of iterations. The results of each iteration are used to develop the next, so that convergence of the experts’ opinions is obtained. ___delphi method___ Question 29 1 / 1 point A type of weighted moving average forecasting technique in which past observations are geometrically discounted according to their age. The heaviest weight is assigned to the most recent data. The smoothing is weighted in accordance with an exponential function of their age. The technique makes use of a smoothing constant. ___Exponential Smoothing Forecast___ Question 30 1 / 1 point A judgmental forecasting technique based on identifying a sales history that is analogous to a present situation, such as the sales history of a similar product, and using that past pattern to predict future sales. Question 31 1 / 1 point The act of clustering several similar services or products so that forecasts and plans can be made for whole families. ___ Question 32 1 / 1 point A set of data that is distributed over time, such as demand data in monthly time periods. Various patterns of demand that are considered include: seasonal, trend, cyclical, and random. Question 33 1 / 1 point Demand that is grouped (e.g., all sedans) for making forecasts or plans. Question 34 0 / 1 point The average of the absolute values of the deviations of observed values from some expected value. It can be calculated based on observations and the arithmetic mean of those observations. Deviation, MAD) Question 35 1 / 1 point The inventory for any grouping of items or products involving multiple stock-keeping units. Question 36 0 / 1 point A process philosophy for facilitating collaborative communications. It is considered a standard, endorsed by the Voluntary Inter-industry Commerce Standards. )___ (Collaborative planning, forecasting, and replenishment (CPFR), Collaborative planning, forecasting, and replenishment, CPFR) Question 37 1 / 1 point An arithmetic average of a certain number (n) of the most recent observations. As each new observation is added, the oldest observation is dropped. The value of n (the number of periods to use or the average) reflects responsiveness versus stability. Question 38 1 / 1 point An estimate of sales, often time-phased, for a grouping of products or product families produced by a facility or firm. Stated in terms of units, dollars, or both, the aggregate forecast is used for sales and production planning (or for sales and operations planning) purposes. Question 39 1 / 1 point A measure of statistical variation in a forecast. Computed by squaring the forecast errors and then taking the average of the sum of the squared errors. Question 40 1 / 1 point An analysis to determine whether a general upward or downward change exists in data. ___trend analysis___ Quiz Submissions - 7810 Week 4 OM9 ch14-Planning Quiz Ashley Robison (username: robisona) Attempt 1 Written: Feb 3, 2015 6:48 PM - Feb 3, 2015 7:44 PM Submission View Your quiz has been submitted successfully. 7810 week 4 OM9 ch14 planning T F questions Question 1 1 / 1 point A master production schedule is a schedule that specifies the timing, size, and sequence of production for aggregated product families. Question 2 1 / 1 point A sales and operations plan is sometimes called an aggregate plan. Question 3 1 / 1 point Complementary products are actions that attempt to modify demand and, consequently, resource requirements. Question 4 1 / 1 point Scheduling is the day-to-day allocation of resources to accomplish specific tasks. Question 5 1 / 1 point Once a demand forecast has been entered into a sales and operations plan, it cannot be updated since it would skew the process results. 7810 week 4 OM9 ch14 planning MC questions Question 6 2 / 2 points Which one of the following conditions can make a level strategy the most attractive? a. The cost of changing the workforce levels is low. b. Products complementary to the existing products can be produced easily with the given facilities. c. The shelf life of the goods being produced is limited. d. Inventory-holding costs are high. Question 7 2 / 2 points The intermediate link between the business plan and the MPS is the: a. annual plan. b. production plan. c. financial plan. d. workforce schedule. Question 8 2 / 2 points Based on the sales and operations plan for a service provider, the next planning level is: a. scheduling. b. annual planning. c. constraint management.. d. resource planning. Question 9 2 / 2 points Which one of the following statements concerning production and staffing plans is best? a. Aggregation can be performed along three dimensions: product families, labor, and time. b. A staffing plan is the intermediate link between the business plan and the master production schedule. c. Production plans are based primarily on information from the master production plan. d. A master production schedule is a projected statement of income, costs, and profits. Question 10 2 / 2 points A sales and operations plan for a service firm is: a. a. a staffing plan. b. a process plan. c. an operations plan. d. a production plan. Question 11 2 / 2 points The planning horizon for a sales and operations plan is typically: a. 0 – 3 months. b. 3 – 18 months. c. 18 – 36 months. d. 36 months – 60 months Question 12 2 / 2 points Which one of the following is a demand option for sales and operations planning? a. Use seasonal inventories to buffer the manufacturing process from variations in customer demand. b. Offer complementary products or services with contra cyclical demand requirements. c. Use overtime and undertime to change workforce levels. d. Use subcontracting to overcome short-term capacity shortages. Question 13 2 / 2 points Which one of the following statements about sales and operations planning is best? a. Supply options are actions that adjust demand patterns. b. All functional areas should supply inputs for developing production and staffing plans. c. The production plan specifies the timing and size of production quantities for each product in the product families. d. The staffing plan is to service organizations what competitive priorities are to manufacturing organizations. 7810 week 4 OM9 ch14 planning FIB questions Question 14 3 / 3 points ____________ ___Complementary products___ are products or services having similar resource requirements but different demand cycles. Question 15 3 / 3 points The ____________ ___master production schedule___ is a schedule that specifies the timing and size of production quantities for each product in the product family. Question 16 3 / 3 points A service firm’s sales and operations plan, called a(n) _________ centers on staffing and other labor-related factors. Question 17 3 / 3 points ____________ ___ takes advantage of the tangible nature of manufactured goods to absorb uneven rates of supply and demand. Key Terms to Know Week 4 Question 18 1 / 1 point The function of recognizing all demands for goods and services to support the marketplace. It involves prioritizing demand when supply is lacking. It facilitates the planning and use of resources for profitable business results. Question 19 1 / 1 point A process that weighs both customer demand and a firm’s output capabilities, and tries to balance the two. It is made up of planning demand, communicating demand, influencing demand, and prioritizing demand. Question 20 1 / 1 point One of the strategic choices that a firm must make as part of its manufacturing strategy. A ______ strategy adds capacity in anticipation of increasing demand. Question 21 1 / 1 point A technique for short-term planning of actual jobs to be run in each work center based upon capacity (i.e., existing workforce and machine availability) and priorities. The result is a set of projected completion times for the operations and simulated queue levels for facilities. Question 22 1 / 1 point A production planning method that maintains a stable inventory level while varying production to meet demand. Companies may combine this method and level production schedule methods. Question 23 1 / 1 point The actual assignment of starting or completion dates to operations or groups of operations to show when these operations must be done if the manufacturing order is to be completed on time. These dates are used in the dispatching function. Question 24 1 / 1 point The agreed-upon plan that comes from the sales and operations planning process, specifically the overall level of manufacturing output planned to be produced, usually stated as a monthly rate for each product family (group of products, items, options, features, and so on). Attempt 1 Submission View Your quiz has been submitted successfully. 7810 week 6 OM8 adj to OM9 ch12 T_F questions Question 1 1 / 1 point Cycle counting is an inventory-control method whereby storeroom personnel physically count a small percent of the total number of items each day. Question 2 1 / 1 point Setup cost is independent of order size. Question 3 1 / 1 point A stockout occurs when an item that is typically stocked is not available to satisfy a demand the moment it occurs. Question 4 1 / 1 point As the service level increases, the probability of not running out of stock during a cycle decreases. Question 5 1 / 1 point A quantity discount is attractive because there is a drop in the price per unit when the order is sufficiently large. Question 6 1 / 1 point One component of the holding cost of inventory is interest. Question 7 1 / 1 point Repeatability is an undesirable feature of some orders because they must be repeated until the order is filled correctly. Question 8 1 / 1 point A backorder occurs when a customer order cannot be filled when it is placed, but is instead filled later. Question 9 1 / 1 point The scheduled receipts are orders that have been placed but not yet received. Question 10 1 / 1 point A continuous review system is sometimes called a reorder point system. 7810 week 6 OM8 adj to OM9 ch12 MC questions Question 11 2 / 2 points ABC analysis is closely related to: a) three-bin analysis. b) EOQ analysis. c) repeatability analysis. d) Pareto analysis. Question 12 2 / 2 points Which of the following factors would cause an operations manager to hold higher inventories? a) A high probability of obsolescence. b) An extremely complicated procedure for adjusting a machine between production of two different types of product. c) An exceedingly high cost of capital. d) A constant item cost regardless of the quantity ordered. Question 13 2 / 2 points One of the secondary levers for reducing pipeline inventory is to: a) offer seasonal pricing plans. b) increase capacity cushions. c) accept only large orders. d) select more responsive suppliers Question 14 2 / 2 points An item that is made to stock or ordered to stock is commonly called a(n): a) SKU. b) standard. c) line item. d) basic. Question 15 2 / 2 points Pipeline inventory is guaranteed to rise if: a) the lot size rises. b) the average demand for the item per unit time falls. c) the lead time rises. d) the cost of capital increases. Question 16 2 / 2 points What is generally about the class A items in ABC analysis? They represent: a) about 20 percent of all items. b) about 30 percent of all items. c) about 20 percent of the dollar usage. d) about 50 percent of the dollar usage. Question 17 0 / 2 points Norman Regional Hospital always kept a few extra heart catheters on hand because when a patient showed up that needed one, they really needed one. This is a prime example of: a) safety stock inventory. b) anticipation inventory. c) pipeline inventory. d) cycle inventory. Question 18 0 / 2 points Which of these statements is NOT a consequence of creating more inventory?. a) Workforce productivity is increased. b) Rescheduling production occurs more frequently. c) The number of setups is reduced. d) Resource utilization is decreased Question 19 2 / 2 points A purchasing agent would be tempted to place a large order if: a) pilferage was approaching record highs. b) equipment setups were quick and easy. c) order receipt procedures were costly. d) the item being ordered was easily obtainable at a half dozen sources in the immediate area. Question 20 0 / 2 points For a company that manufactures most of its products as standards, more inventory should be placed: a) closer to the customer. b) within the plant as work-in-process. c) close to suppliers. d) equally distributed between the plants and warehouses. 7810 week 6 OM9 Ch12 FIB questions Question 21 3 / 3 points A(n) ____________ system is a system designed to track the remaining inventory of an item each time a withdrawal is made to determine whether to replenish the item. Question 22 3 / 3 points The ____________ is the predetermined minimum level that an inventory position must reach before a fixed quantity (Q) is ordered. Question 23 3 / 3 points The number of setups (or orders) per year is determined by the annual demand and ____________. Question 24 3 / 3 points In an EOQ model, as the ordering cost for an item decreases, the EOQ for the item __ Question 25 3 / 3 points The ____________ is the average elapsed time between receiving replenishment orders of Q units for a particular lot size. Question 26 3 / 3 points When considering dependent / independent demand, in the example of tires and automobiles, the original equipment tires represent -demand items, while automobiles s represent a(n) -demand item. Question 27 3 / 3 points A periodic review/reorder system is also known as a(n) ) ____________ system. Question 28 3 / 3 points In an ABC analysis, the class _____ SKUs, which typically make up about ______ % of the SKUs, account for about 5% of the dollar usage. Question 29 3 / 3 points ____________ -demand items are items for which demand is influenced by market conditions and is not related to the inventory decisions for any other item held in stock. Question 30 3 / 3 points In an ABC analysis, the class _____ SKUs, which typically make up about ______ % of the SKUs, account for about 80% of the dollar usage. Key Terms to Know Week 6 Question 31 1 / 1 point The predetermined minimum level that an inventory position must reach before a fixed quantity (Q) of the SKU is ordered in a continuous review (Q) system. Question 32 1 / 1 point A system designed to track the remaining inventory of a SKU each time a withdrawal is made to determine whether it is time to reorder. Question 33 1 / 1 point A form of independent demand management model in which an order is placed every n time units. Question 34 1 / 1 point A form of independent demand item management model in which an order for a fixed quantity, Q, is placed whenever stock on hand plus on order reaches a predetermined reorder level, R. Question 35 1 / 1 point A lot-sizing technique under which the lot size is equal to the net requirements for a given number of time units (e.g., weeks into the future). The number of time units to order is variable, each order size equalizing the holding costs and the ordering costs for the selected interval. Question 36 0 / 1 point A type of model where uncertainty is explicitly considered in the analysis. stochastic models, stochastic) Question 37 1 / 1 point A lot-sizing technique in MRP or inventory management that will always cause planned or actual orders to be generated for a predetermined fixed quantity, or multiples thereof, if net requirements for the period exceed the defined requirements. Question 38 1 / 1 point The lot size that minimizes total annual inventory holding and ordering costs Question 39 1 / 1 point An inventory item. For example, a shirt in six colors and five sizes would represent 30 of these. Question 40 1 / 1 point The activities and techniques of determining the desired levels of items, whether raw materials, work in process, or finished products including order quantities and safety stock levels. ________________________________________ Quiz Submissions - 7810 Week 7 OM9 Supplement D Quiz Ashley Robison (username: robisona) Attempt 1 Written: Feb 28, 2015 10:08 PM - Mar 4, 2015 4:58 AM Submission View Your quiz has been submitted successfully. 7810 week 7 suppD T_F questions OM8 and OM9 Question 1 1 / 1 point The one-period inventory model is commonly known as the newsboy problem. Question 2 1 / 1 point The economic production lot size represents the maximum quantity of on-hand inventory for a manufacturer. Question 3 1 / 1 point For analysis using the economic production lot size (ELS) model to be useful, the producer must be able to produce the item faster than it is consumed. Question 4 1 / 1 point When facing quantity discounts, the EOQ found with the lowest price level is the lowest total cost plan. 7810 week 7 SuppD MC questions OM8 and OM9 Question 5 2 / 2 points Use the information in Scenario D.2. What is the payoff with an order quantity (Q) of 40 units if the demand (D) is 30 units? Scenario D.2 Kyle store sells K2 skis. The store makes a $200 profit per unit sold during the ski season, but it should take a $50 loss per unit if sold after the season is over. The following discrete probability distribution has been estimated for the season’s demand. Demand (D) Demand Probability 10 0.1 20 0.3 30 0.3 40 0.2 a) Less than or equal to $2,000 b) Greater than $2,000 but less than or equal to $4,000 c) Greater than $4,000 but less than or equal to $6,000 d) Greater than $6,000 Question 6 2 / 2 points Warren’s Ice Cream makes 4 different flavors of ice cream using their secret process and top secret recipes. Each of their flavors is equally popular and experiences a demand of 5000 gallons/year. Warren’s process is capable of producing 100 gallons/day once they incur the $25 setup cost. The ice cream holding cost is 10% of the $5 per gallon price. Warren’s plant runs 250 days a year and stays busy doing so but management feels they can add another flavor to their product line and increase their revenue. Which of the following statements is appropriate for this scenario? a) Warren’s can comfortably add a fifth flavor without increasing the number of days they operate. b) Warren’s cannot add the fifth flavor because the holding cost would increase. c) Warren’s can add the fifth flavor only if there is zero setup time between flavors. d) Warren’s cannot add the fifth flavor because demand would exceed capacity. Question 7 2 / 2 points Use the information in Scenario D.1. How many production runs per year are needed if Jerry chooses to produce at his economic production lot size (ELS)? Scenario D.1 Jerry Allison is in charge of production for a small producer of plumbing supplies. The cricket model has an estimated annual demand of 12,000 units and can be produced at a production rate of 90 units per day. The company produces (and sells) the cricket 300 days per year. Setup cost to produce this model averages $22 and the item has a holding cost of $3 per unit per year. Fewer than or equal to 10 runs Greater than 10 runs but fewer than or equal to 20 runs Greater than 20 runs but fewer than or equal to 30 runs Greater than 30 runs Question 8 2 / 2 points In a noninstantaneous replenishment model, as the daily demand approaches 50% of the daily production rate: a) the number of production runs per year decreases. b) the length in days of a production run increases. c) the economic lot size increases. d) the time between production runs decreases. Question 9 2 / 2 points Use the information in Scenario D.2. What is the best order quantity? Scenario D.2 Kyle store sells K2 skis. The store makes a $200 profit per unit sold during the ski season, but it should take a $50 loss per unit if sold after the season is over. The following discrete probability distribution has been estimated for the season’s demand. Demand (D) Demand Probability 10 0.1 20 0.3 30 0.3 40 0.2 a) Fewer than or equal to 20 units b) Greater than 20 units but fewer than or equal to 40 units c) Greater than 40 units but fewer than or equal to 50 units d) Greater than 50 units Question 10 2 / 2 points Pencil supplier just introduced quantity discounts. The price schedule follows. Order Quantity Price per Unit 000–199 $4.00 200–399 $3.00 400 and more $2.00 XYZ store’s annual demand remains at 500 units and ordering cost at $10 per order. If annual holding cost is 10 percent of the pencils’ per-unit price, what order quantity should XYZ select to minimize all costs? a) Fewer than or equal to 150 units b) Greater than 150 units but fewer than or equal to 199 units c) Greater than 199 units but fewer than or equal to 399 units d) Greater than 399 units Question 11 2 / 2 points Use the information in Scenario D.1. If Jerry chooses to produce the batch size suggested by the economic production lot size (ELS) model, what is the annual cost? Scenario D.1 Jerry Allison is in charge of production for a small producer of plumbing supplies. The cricket model has an estimated annual demand of 12,000 units and can be produced at a production rate of 90 units per day. The company produces (and sells) the cricket 300 days per year. Setup cost to produce this model averages $22 and the item has a holding cost of $3 per unit per year. a) Less than or equal to $900 b) Greater than $900 but less than or equal to $950 c) Greater than $950 but less than or equal to $1000 d) Greater than $1000 Question 12 2 / 2 points Use the information in Scenario D.1. What is the maximum inventory if Jerry chooses to produce at the economic production lot size (ELS)? Scenario D.1 Jerry Allison is in charge of production for a small producer of plumbing supplies. The cricket model has an estimated annual demand of 12,000 units and can be produced at a production rate of 90 units per day. The company produces (and sells) the cricket 300 days per year. Setup cost to produce this model averages $22 and the item has a holding cost of $3 per unit per year. a) Fewer than or equal to 300 units b) Greater than 300 units but fewer than or equal to 320 units c) Greater than 320 units but fewer than or equal to 340 units d) Greater than 340 units 7810 OM9 SupD Problems Question 13 5 / 5 points As an inventory manager, you must decide on the order quantity for an item. Its annual demand is 1,000 units. Ordering costs are $50 each time an order is placed, and the holding cost is 25 percent of the per-unit price. Your supplier provided the following price schedule. Quantity Price per Unit 1–199 $10.00 200–499 $ 9.80 500 or more $ 9.60 What ordering-quantity policy do you recommend? enter the number with no decimal places (xxx) ___202___ Quiz Submissions - 7810 Week 9 OM9 ch7 Quiz Ashley Robison (username: robisona) Attempt 1 Written: Mar 15, 2015 3:02 PM - Mar 15, 2015 7:56 PM Submission View Your quiz has been submitted successfully. OM9 ch7 T F questions Question 1 1 / 1 point Short term capacity planning should be driven by identification and management of bottlenecks. Question 2 1 / 1 point A competent operations manager should first eliminate all of the bottlenecks from the process. Question 3 1 / 1 point Immediate predecessors are the smallest units of work that can be performed independently. Question 4 1 / 1 point According to the Theory of Constraints, the four operational measures include inventory, throughput, delivery lead times and utilization. Question 5 1 / 1 point The process with the least capacity is called a bottleneck if its output is still greater than the market demand. Question 6 1 / 1 point Line balancing applies only to line processes that do assembly work, or to work that can be bundled in many ways to create the jobs for each workstation in the line. OM9 ch7 MC questions Question 7 2 / 2 points The process batch at the constraint in a drum-buffer-rope system should: a. be the same size as that at any non-constraint. b. be the same size as the transfer batch. c. be of such a size as to maximize the number of setups for the constraint d. be of such a size as to improve utilization of the constraint. Question 8 2 / 2 points Practical application of the Theory of Constraints involves the implementation of all of the following steps EXCEPT: a. Identify the system bottleneck(s). b. Exploit the bottleneck(s). c. Reduce the capacity at the bottleneck(s). d. Elevate the bottleneck(s). Question 9 2 / 2 points A line-balancing solution has been developed for the assembly line for fertilizer spreaders at Green Grass, Inc. The desired output rate of 30 spreaders per hour will be achieved. The sum of times for all tasks performed on the line is 1200 seconds for each spreader assembled. This is the total productive time. Which of the following statements must be ? a. The cycle time is 30 seconds per spreader. b. The theoretical minimum number of stations is 10. c. If the solution calls for 11 stations, the efficiency is 80%. d. If the solution calls for 12 stations, the efficiency is 80%. Question 10 2 / 2 points In a drum-buffer-rope system, the small lot size that moves from one work center to another for additional processing is a(n): a. process batch. b. operations batch. c. transfer batch. d. rope batch. Question 11 2 / 2 points The focus for a process improvement exercise should be on balancing: a. flow. b. capacity. c. workload. d. time. Question 12 2 / 2 points The fourth step in Theory of Constraints application, “elevate the bottleneck(s),” means that: a. the analyst should create a schedule that maximizes the throughput of the bottlenecks. b. the analyst should repeat the analysis process to look for other bottlenecks. c. the analyst should consider increasing capacity of the bottleneck. d. the analyst should schedule non-bottleneck resources to support the bottleneck. OM9 ch7 FIB questions Question 13 3 / 3 points A(n) ____________ ___mixed-model___ line is a product line that produces several items belonging to the same family. Question 14 3 / 3 points The movement of product from one station to the next as soon as the cycle time has elapsed is called ____________ ___pacing___ Question 15 3 / 3 points With TOC, ____________ ___bottlenecks___ are scheduled to maximize their throughput of products while adhering to promised completion dates. Question 16 3 / 3 points Every time a manufacturer uses one resource, they make a lot size of 300. Once a group of 30 units are completed, they are taken to the next step in the process. The lot of 300 is the ____________ ___production batch___ (50 %) and the group of 30 is the ____________ ___transfer batch___ (50 %) Question 17 3 / 3 points ____________ ___Balance delay___ is the amount by which efficiency falls short of 100 percent. Key Terms to Know Week 9 Question 18 1 / 1 point The practice of managing resources and organizations in accordance with the theory of constraints (TOC) principles. ___constraint management___ (constraints management) Question 19 1 / 1 point The resource capacity needed to protect system throughput—ensuring that some capacity above the capacity required to exploit the constraint is available to catch up when disruptions inevitably occur. ___protective capacity___ Question 20 1 / 1 point Any element or factor that prevents a system from achieving a higher level of performance with respect to its goal. These can be physical, such as a machine center or lack of material, but they can also be managerial, such as a policy or procedure. ___Constraint (process engineering)___ (constraint) Question 21 1 / 1 point In the theory of constraints, a logic-based tool for constructing and testing potential solutions before implementation. ___future reality tree___ Question 22 1 / 1 point In the critical path method of project management, a logical relationship that one node has to the succeeding node. ___precedence diagram method also activity-on-node network (AON)___ (precedence relationship, logical relationship, dependency, precedence) Question 23 1 / 1 point In the theory of constraints, the constraint is viewed as this, and non-constraints are like soldiers in an army who march in unison to the pace set by this. ___drum___ Question 24 1 / 1 point A finite loading technique that plans orders around bottleneck work centers. The objective is to maximize total production throughput. Orders in small lot sizes aggregate into large lot sizes at the constraint and then load forward. Prior operations are then backward-scheduled, and downstream operations are forward-scheduled. ___constraint-oriented finite loading___ Question 25 1 / 1 point A quantity of materials awaiting further processing. It can refer to raw materials, semi-finished stores or hold points, or a work backlog that is purposely maintained behind a work center. ___buffer___ Question 26 1 / 1 point In the theory of constraints, a network planning technique for the analysis of a project’s completion time, used for planning and controlling project activities. This determines project duration and is based on technological and resource constraints. It provides strategic buffering of paths and resources to increase project completion success. ___Critical chain method___ Question 27 1 / 1 point A holistic management philosophy developed by Dr. Eliyahu M. Goldratt that is based on the principle that complex systems exhibit inherent simplicity. Even a very complex system comprising thousands of people and pieces of equipment can have, at any given time, only a very, very small number of variables—perhaps only one— that actually limit the ability to generate more of the system’s goal. ___Theory of Constraints (TOC)___ Question 28 1 / 1 point The function of establishing, measuring, monitoring, and adjusting limits or levels of capacity in order to execute all manufacturing schedules (i.e., the production plan, master production schedule, material requirements plan, and dispatch list). This is executed at four levels: resource requirements planning, rough-cut capacity planning, capacity requirements planning, and input/output control. ___Capacity Management___ Question 29 1 / 1 point A resource that is not a constraint but will become a constraint unless scheduled carefully. Any resource that, if its capacity is not carefully managed, is likely to compromise the throughput of the organization. ___capacity-constrained resource (CCR)___ Question 30 1 / 1 point The process of measuring production output and comparing it with the capacity plan, determining if the variance exceeds pre-established limits, and taking corrective action to get back on plan if the limits are exceeded. ___Capacity control___ Question 31 1 / 1 point A facility, function, department, or resource whose capacity is less than the demand placed upon it. For example, it exists where jobs are processed at a slower rate than they are demanded. ___Bottleneck___ Question 32 1 / 1 point A manufacturing management philosophy that includes a consistent set of principles, procedures, and techniques where every action is evaluated in terms of the global goal of the system. Both kanban, which is a part of the JIT philosophy, and drum-buffer-rope, which is a part of the theory of constraints philosophy, represent this production control approache. ___Synchronized production___ Quiz Submissions - 7810 Week 10 OM9 ch15 Quiz Ashley Robison (username: robisona) Attempt 1 Written: Mar 19, 2015 4:54 AM - Mar 19, 2015 6:03 PM Submission View Your quiz has been submitted successfully. OM9 Ch15 T-F Question 1 1 / 1 point For items manufactured in-house, one component of the planned lead time is waiting time. Question 2 1 / 1 point Available-to-promise inventory is the amount of end items that marketing can promise to customers by a certain date. Question 3 1 / 1 point An ERP system revolves around a single comprehensive database that is made available across the entire organization. Question 4 1 / 1 point Gross requirements are the total demand derived from all parent production plans. Question 5 1 / 1 point Material requirements planning (MRP) is a computerized information system developed specifically to aid in managing dependent demand inventory and scheduling replenishment orders. Question 6 1 / 1 point MRP II ties MRP to the company’s financial system. Question 7 1 / 1 point The projected on-hand inventory in the MPS takes into account customer orders (booked) as well as the MPS quantities. Question 8 1 / 1 point The process with the least capacity is called a capacity constrained resource if its output is less than market demand. Question 9 1 / 1 point Companies that fully customize their ERP implementation reap the greatest rewards from such systems since they can continue to use the same processes to which all employees are accustomed. Question 10 1 / 1 point An intermediate item must have at least one parent and at least one component. OM9 Ch15 MC Question 11 2 / 2 points Which of the following statements about ERP systems is best? a. Recent studies have shown that the most successful ERP implementations use standardized systems. b. ERP systems written in XML require complete replacements of a company’s legacy systems. c. A company must adapt their ERP system to their existing processes in order for all employees to gain a benefit from the new system. d. An ERP system requires a regular synchronization of all of the module databases, which is usually accomplished automatically when the business is not conducting business. Question 12 2 / 2 points Which best defines the gross requirements for a component item? a. The forecasted customer demand for the component b. The amount of safety stock needed to buffer against uncertainties c. The sum of gross requirements for all parents of the component d. The total demand for the component derived from all immediate parents Question 13 2 / 2 points Which one of the following is an input to the MRP system? a. Shop-floor schedules b. Financial reports c. Master production schedule d. Purchasing orders Question 14 2 / 2 points Entering new information in the database of an ERP system is a(n): a. data packet. b. transaction. c. record. d. file. Question 15 2 / 2 points If a planned receipt for an item is due in week 6 and the item’s lead time is two weeks, in which week will the corresponding planned order release occur? a. Week 2 b. Week 4 c. Week 6 d. Week 8 Question 16 2 / 2 points Management wishes to use a POQ lot-sizing rule for an item that experiences an average demand of 30 units per week. If the desired average lot size is 120 units, what should P be? a. Zero or one weeks b. Two or three weeks c. Four or five weeks d. More than five weeks Question 17 2 / 2 points Which of the following is NOT an example of dependent demand items? a. Shoelaces, shoes b. Wheels, car c. Carafes, coffeemakers d. Ice skates, roller skates Question 18 2 / 2 points A computer-generated memo used by inventory planners to make decisions about releasing new orders and adjusting due dates of scheduled receipts is a(n): a. enterprise report. b. infinite capacity. c. action notice. d. input–output report. Question 19 2 / 2 points Which statement on MRP explosion is best? a. It calculates the total number of subassemblies, components, and raw materials needed for each parent item. b. It calculates the total number of raw materials to be purchased from all suppliers. c. It calculates the total number of parts to be produced for each parent item. d. It calculates the total number of parts needed to be produced less the number of parts on hand for each parent item. Question 20 2 / 2 points Which of the following statements about service resource planning is ? a. The service analogy to the BOM in a manufacturing company is a bill of lading (BOL). b. One resource that every service provider manages is cash. c. There is no such thing as dependent demand in the service sector. d. As services are completed, the accounts receivable decrease. Question 21 2 / 2 points Which one of the following is an MRP lot-sizing rule that attempts to minimize the amount of average inventory? a. Periodic order quantity (POQ), with P = 2 b. Fixed order quantity (FOQ) c. Economic order quantity (EOQ) d. Lot for lot (L4L) OM9 Ch15 FIB Question 22 3 / 3 points A companywide process that cuts across functional areas, business units, geographic regions, and product lines is a(n) ____________ ___enterprise process___ Question 23 3 / 3 points ____________ ___Scheduled receipts___ are orders that have been placed but not yet completed. Question 24 3 / 3 points In MRP, a(n) ____________ ___parent___ is any item manufactured from one or more components. Question 25 3 / 3 points A(n ) ____________ ___purchased___ item has one or more parents but no components. Question 26 3 / 3 points A(n) ____________ ___remnant___ is inventory carried into a week but too small to prevent a shortage. Question 27 3 / 3 points ____________ ___Manufacturing Resource Planning___ ties the basic MRP system to the company’s financial system. Question 28 3 / 3 points A(n) ____________ ___bill of resources___ is a record of a service firm’s parent-component relationships all of the materials, equipment, time, staff, and other productive assets associated with them, including usage quantities. Question 29 3 / 3 points ____________ ___Lot-for-lot___ is a lot-sizing rule under which the lot size ordered covers the gross requirements of a single week. Question 30 3 / 3 points ____________ ___Projected on-hand inventory___ is an estimate of the amount of inventory available each week after gross requirements have been satisfied. Key Terms to Know Week 10 Question 31 1 / 1 point The on-hand inventory balance minus allocations, reservations, backorders, and (usually) quantities held for quality problems. ___Available Inventory___ Question 32 1 / 1 point Techniques that deal with analysis and planning of logistics and manufacturing during short, intermediate, and long-term time periods. This term describes any computer program that uses advanced mathematical algorithms or logic to perform optimization or simulation on finite capacity scheduling, sourcing, capital planning, resource planning, forecasting, demand management, and others. ___advanced planning and scheduling (APS)___ (advanced planning and scheduling, advanced planning and scheduling, APS) Question 33 1 / 1 point A statement of on-hand quantities or the dollar value of a SKU at the end of a period, often determined by a physical inventory ___ending inventory___ Question 34 0 / 1 point A dynamic lot-sizing technique that uses the same logic as the least total cost method, but adds a routine called look ahead/look back. ___part number___ (part period balancing (PPB), part period balancing, PPB) Question 35 1 / 1 point A dynamic lot-sizing technique that adds ordering cost and inventory carrying cost for each trial lot size and divides by the number of units in the lot size, picking the lot size with the lowest unit cost. ___Least unit cost method___ (least unit cost) Question 36 1 / 1 point A listing of the required capacity and key resources needed to manufacture one unit of a selected item or family. ___A bill of resources___ (bill of resources) Question 37 1 / 1 point A listing of all the subassemblies, intermediates, parts, and raw materials that go into a parent assembly showing the quantity of each required to make an assembly. ___Bill of Material___ Question 38 1 / 1 point The function of establishing, measuring, and adjusting limits or levels of capacity. The term in this context refers to the process of determining in detail the amount of labor and machine resources required to accomplish the tasks of production. ___Capacity Requirements Planning (CRP)___ Question 39 1 / 1 point A dynamic lot-sizing technique that calculates the order quantity by comparing the setup (or ordering) costs and the carrying cost for various lot sizes and selects the lot size where these costs are most nearly equal. ___least total cost___ Question 40 1 / 1 point The quantity shown in the inventory records as being physically in stock. ___on hand balance___ (on-hand balance) Quiz Submissions - 7810 Week 12 OM9 ch14-Scheduling Quiz Ashley Robison (username: robisona) Attempt 1 Written: Apr 1, 2015 4:31 AM - Apr 1, 2015 4:59 AM Submission View Your quiz has been submitted successfully. OM9 Ch14 sch T F questions Question 1 1 / 1 point Undertime is the situation that occurs when employees do not have enough productive work for the regular-time workday or workweek. Question 2 1 / 1 point Earliest due date (EDD) is a priority-sequencing rule that states the job requiring the shortest processing time is the next job to be processed. Question 3 1 / 1 point Advanced planning and scheduling systems (APS) seek to optimize resources across the supply chain and align daily operations with strategic goals. Question 4 1 / 1 point A fixed schedule gives each employee the next employee’s schedule the following week. Question 5 1 / 1 point The Gantt chart can be used as a tool for sequencing work on machines and monitoring its progress. OM9 ch14 sch MC questions Question 6 2 / 2 points The workforce schedule: a. determines when employees work. b. determines how many workers are needed over an extended horizon. c. determines the daily worker requirements. d. specifies the specific task each worker is to do and when. Question 7 2 / 2 points Which one of the following approaches for scheduling customer demand would be appropriate for a dentist? a. Backlogs b. Reservations c. Service on demand d. Appointments Question 8 2 / 2 points Which one of the following approaches for scheduling customer demand would be appropriate for a fancy hotel? a. Backlogs b. Reservations c. Service on demand d. Appointments Question 9 2 / 2 points A service provider assigns a specific time for personal service to a customer with a(n): a. backlog. b. reservation. c. service on demand. d. appointment. Question 10 2 / 2 points The lowest planning level in a sales and operations plan is: a. resource planning. b. forecasting. c. scheduling. d. sales and operations planning. Question 11 2 / 2 points Job flow time is defined as the: a. time of completion of a job plus the time it was available in a work station. b. processing time to complete a particular job. c. time of completion of the last job of a group minus the starting time of the first job. d. amount of time by which a group of jobs missed their due dates. Question 12 2 / 2 points The purpose of a rotating schedule is to: a. assign each employee to work the same days and hours each week. b. assign senior employees more opportunity to have weekends off. c. deal with certain undesirable aspects of several individual workforce schedules. d. make sure the legal constraints imposed on workforce schedules are satisfied. OM9 ch14 sch FIB questions Question 13 3 / 3 points ____________ specify the job processing sequence when several jobs are waiting in line at a workstation. Question 14 3 / 3 points A(n) ____________ graphically displays the current status of each job or activity relative to its scheduled completion date. Question 15 3 / 3 points A(n) ____________ seeks to optimize resources across the supply chain and align daily operations with strategic goals. Question 16 3 / 3 points ____________ ___Scheduling___ takes the operations and scheduling process from planning to execution. Question 17 3 / 3 points ____________ scheduling assigns jobs to machines or workers to jobs. Question 18 3 / 3 points ____________ is a priority sequencing rule that specifies that the job that arrived at the workstation first is given the highest priority. Question 19 3 / 3 points A hospital must have a skeleton crew on hand during the undesirable work period from midnight to 8 o’clock. One way to make sure that all employees have the opportunity to work this shift is by adopting a(n) ____________. _ Key Terms to Know Week 12 Question 20 1 / 1 point A dispatching rule that selects the job having the earliest due date for the impending operation. Question 21 1 / 1 point The logic used to assign priorities to jobs at a work center. Question 22 1 / 1 point A method of inventory valuation for accounting purposes. The accounting assumption is that the oldest inventory (first in) is the first to be used (first out), but there is no necessary relationship with the actual physical movement of specific items. ___First in, First out___ Question 23 1 / 1 point The earliest date an operation or order can start. It may be restricted by the current date, material availability, or management-specified “maximum advance.” [Show More]

Last updated: 1 year ago

Preview 1 out of 53 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Add to cartInstant download

We Accept:

Reviews( 0 )

$12.00

Document information

Connected school, study & course

About the document

Uploaded On

Sep 19, 2020

Number of pages

53

Written in

Additional information

This document has been written for:

Uploaded

Sep 19, 2020

Downloads

0

Views

53