Engineering > SOLUTIONS MANUAL > ENGI 9340: Materials Degradation in Process Engineering (Spring 2020) Solutions Assignment 3 (All)

ENGI 9340: Materials Degradation in Process Engineering (Spring 2020) Solutions Assignment 3

Document Content and Description Below

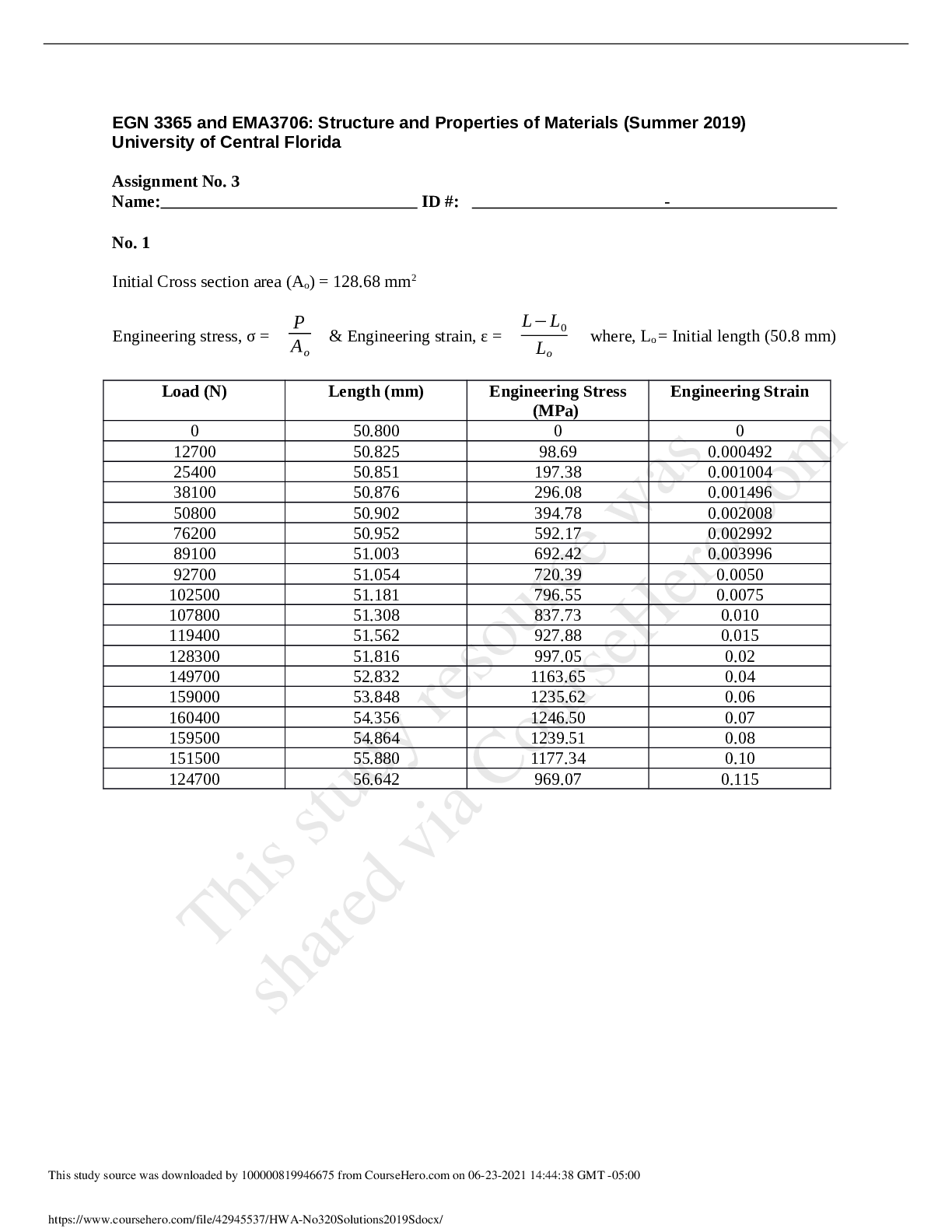

1 ENGI 9340: Materials Degradation in Process Engineering (Spring 2020) Solutions Assignment 3 1. An attempt is made to laser surface harden a carbon steel in open air. The treated surface is very... rough and heavily contaminated with iron oxide. What is the likely cause of the poor surface quality and its probable remedy? (15 points) 2. A component, about 100 mm in largest dimension, is brought into a laboratory to determine whether corrosion is the cause of loss of material around some external surfaces of the component, which originally had a coating. The component shows unusual deposits of powder material on the same external surfaces. Discuss, with reasons, the likely strategy to determine whether corrosion has been the cause of damage to this metal component. (15 points) 3. As part of a program to evaluate the durability of outdoor coatings over a period of several years with the purpose of estimating the future durability of the coatings; test panels are brought in for microscopic examination at periodic intervals and then returned to the outdoor test-site. Suggest a method of microscopy to obtain all (or virtually all) significant information within a reasonable amount of time. (15 points) 4. The rotating vanes of an undersea tidal power device need surface engineering to ensure long service lifetimes for these poorly accessible devices. The tidal power collection device consists of a fan (containing the vanes) connected to a sealed generator and mounted on an anchored column. Discuss the prevailing conditions and suggest some probable coatings. The vanes are made of high strength steel, chosen for the moderate cost of steel and the benign nature of rust in the marine environment. (15 points) 5. The dies of a hydraulic press used to produce car bodies suffers from extensive scratching after about 100,000 cycles. The die has to be replaced or repaired once extensive scratching occurs. Production runs of the body shape usually reach 1,000,000 units or more. Suggest a suitable surface coating technology to suppress the scratching for at least 1,000,000 cycles. (10 points) 6. Please summarize the coating technologies available for prevention of material degradations, giving their applications and advantages/disadvantages. (30 points) [Show More]

Last updated: 1 year ago

Preview 1 out of 13 pages

Reviews( 0 )

Document information

Connected school, study & course

About the document

Uploaded On

Jul 29, 2021

Number of pages

13

Written in

Additional information

This document has been written for:

Uploaded

Jul 29, 2021

Downloads

0

Views

38

.png)

, 2e by Stephen Lovett.png)