Financial Accounting > QUESTIONS & ANSWERS > American Public University - ACC 300Assignment 11. Questions and Answers. Score: 35.42 out of 50 poi (All)

American Public University - ACC 300Assignment 11. Questions and Answers. Score: 35.42 out of 50 points (70.84%).

Document Content and Description Below

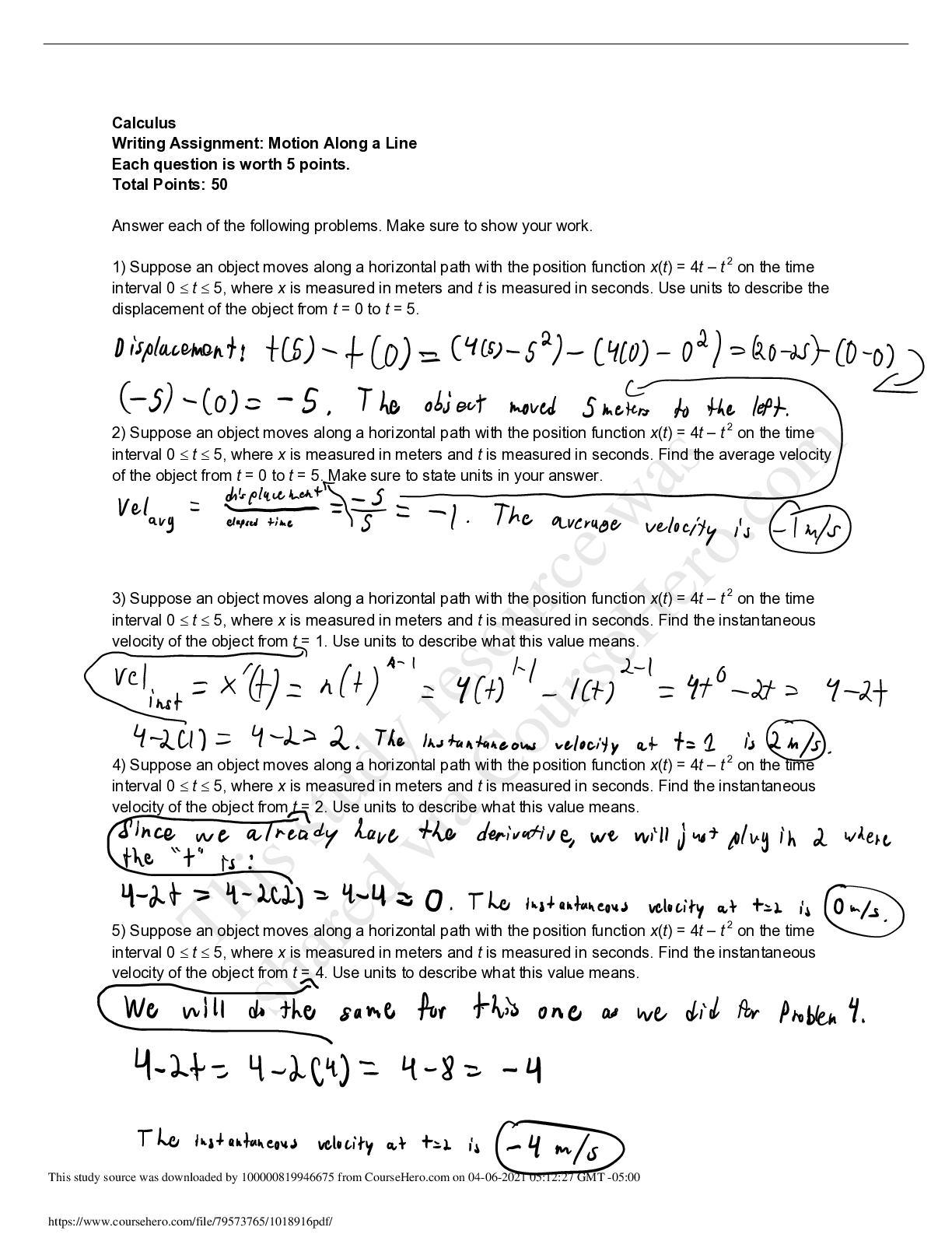

Score: 35.42 out of 50 points (70.84%) 1. Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate plan given the forecast for engine demand show... n in the table. The department has a normal capacity of 130 engines per month. Normal output has a cost of $60 per engine. The beginning inventory is zero engines. Overtime has a cost of $90 per engine. Month a. Develop a chase plan that matches the forecast and compute the total cost of your plan. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) Total $ 7,200 8,250 8,700 7,200 7,500 7,500 8,700 8,250 b. Compare the costs to a level plan that uses inventory to absorb fluctuations. Inventory carrying cost is $2 per engine per month. Backlog cost is $90 per engine per month. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) Worksheet Learning Objective: 11-03 Describe some of the strategies that can be used for meeting uneven demand. Learning Objective: 11-05 Prepare aggregate plans and Problem 11-5 compute their costs. Problem 11-5 Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate plan given the forecast for engine demand shown in the table. The department has a normal capacity of 130 engines per month. Normal output has a cost of $60 per engine. The beginning inventory is zero engines. Overtime has a cost of $90 per engine. Month 1 2 3 4 5 6 7 8 Total Forecast 120 135 140 120 125 125 140 135 1,040 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) Total $ 7,200 8,250 8,700 7,200 7,500 7,500 8,700 8,250 b. Compare the costs to a level plan that uses inventory to absorb fluctuations. Inventory carrying cost is $2 per engine per month. Backlog cost is $90 per engine per month. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) × 90 = 0 Problem 11-6 Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a normal capacity of 275(00) bolts per month, except for the seventh month, when capacity will be 250(00) bolts. Normal output has a cost of $40 per hundred bolts. Workers can be assigned to other jobs if production is less than normal. The beginning inventory is zero bolts. Month 1 2 3 4 5 6 7 Total Forecast 250 300 250 300 280 275 270 1,925 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $60 per hundred bolts. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) Period 1 2 3 4 5 6 7 Total Forecast 250 300 250 300 280 275 270 Output Regular 250 275 250 275 275 275 250 1,850 Overtime 0 25 0 25 5 0 20 Subcontract Output - Forecast Inventory Beginning Ending Average Backlog Costs: Output Regular $ 10,000 11,000 10,000 11,000 11,000 11,000 10,000 $ 74,000 Overtime 0 1,500 0 1,500 300 0 1,200 4,500 Subcontract Inventory Backorder Total $ 10,000 12,500 10,000 12,500 11,300 11,000 11,200 $ 78,500 b. Would the total cost be less with regular production with no overtime, but using a subcontractor to handle the excess above normal capacity at a cost of $50 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts. (Round your Average values to 1 decimal place. Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) Subcontract 0 0 0 0 250 0 1,000 1,250 Inventory 25 25 25 25 0 0 0 Backorder 0 0 0 0 0 0 0 Total $ 11,025 11,025 11,025 11,025 11,250 11,000 11,000 $ 77,350 Problem 11-6 Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a normal capacity of 275(00) bolts per month, except for the seventh month, when capacity will be 250(00) bolts. Normal output has a cost of $40 per hundred bolts. Workers can be assigned to other jobs if production is less than normal. The beginning inventory is zero bolts. Month 1 2 3 4 5 6 7 Total Forecast 250 300 250 300 280 275 270 1,925 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $60 per hundred bolts. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) b. Would the total cost be less with regular production with no overtime, but using a subcontractor to handle the excess above normal capacity at a cost of $50 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts. (Round your Average values to 1 decimal place. Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) Wormwood, Ltd., produces a variety of furniture products. The planning committee wants to prepare an aggregate plan for the next six months using the following information: MONTH 1 2 Cost Per Unit Regular time $50 Overtime 75 Subcontract 80 Inventory, per period 4 Subcontracting can handle a maximum of 10 units per month. Beginning inventory is zero. Develop a plan that minimizes total cost. No back orders are allowed. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) Worksheet Learning Objective: 11-03 Describe some of the strategies that can be used for meeting uneven demand. Problem 11-9 Learning Objective: 11-05 Prepare aggregate plans and compute their costs. Problem 11-9 Wormwood, Ltd., produces a variety of furniture products. The planning committee wants to prepare an aggregate plan for the next six months using the following information: MONTH 1 2 3 4 5 6 Demand 160 150 160 180 170 140 Capacity Regular 150 150 150 150 160 160 Overtime 10 10 0 10 10 10 Cost Per Unit Regular time $50 Overtime 75 Subcontract 80 Inventory, per period 4 Subcontracting can handle a maximum of 10 units per month. Beginning inventory is zero. Develop a plan that minimizes total cost. No back orders are allowed. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required. Omit the "$" sign in your response.) 4. award: Problem 11-14 Given the following information set up the problem in a transportation table and solve for the minimum-cost plan: (Omit the "$" sign in your response.) PERIOD 1 2 3 Demand 550 700 750 Capacity Regular 500 500 500 Overtime 50 50 50 Subcontract 120 120 100 Beginning inventory 100 Costs Regular time $ 60 per unit Overtime $ 80 per unit Subcontract $ 90 per unit Inventory carrying cost $ 1 per unit per month Back-order cost $ 3 per unit per month Minimum total cost $ 125,344 Worksheet Problem 11-14 Learning Objective: 11-05 Prepare aggregate plans and compute their costs. Problem 11-14 Given the following information set up the problem in a transportation table and solve for the minimum-cost plan: (Omit the "$" sign in your response.) PERIOD 1 2 3 Demand 550 700 750 Capacity Regular 500 500 500 Overtime 50 50 50 Subcontract 120 120 100 Beginning inventory 100 Costs Regular time $ 60 per unit Overtime $ 80 per unit Subcontract $ 90 per unit Inventory carrying cost $ 1 per unit per month Back-order cost $ 3 per unit per month Minimum total cost $ 124,730 Explanation: award: 5.42 out of 10.00 points Problem 11-19 Prepare a master production schedule for industrial pumps in the manner of the following table. Use the MPS rule to "schedule production when the projected on-hand inventory would be less than 10 without production." Suppose that a production lot size of 70 pumps is used. (Leave no cells blank - be certain to enter "0" wherever required.) June July 64 1 2 3 4 5 6 7 Forecast 30 30 30 30 40 40 40 Customer orders (committed) 33 20 10 4 2 Projected on-hand inventory 31 11 41 11 41 1 31 MPS 0 0 29 0 70 0 70 ATP 0 0 56 0 68 0 70 Worksheet Problem 11-19 Learning Objective: 11-08 Describe the master scheduling process and explain its importance. Problem 11-19 Prepare a master production schedule for industrial pumps in the manner of the following table. Use the MPS rule to "schedule production when the projected on-hand inventory would be less than 10 without production." Suppose that a production lot size of 70 pumps is used. (Leave no cells blank - be certain to enter "0" wherever required.) June July Explanation: Week Inventory From Previous WK. Requirements Net Inventories Before MPS (70) MPS Projected On-Hand Inventory [Show More]

Last updated: 1 year ago

Preview 1 out of 8 pages

Instant download

Buy this document to get the full access instantly

Instant Download Access after purchase

Add to cartInstant download

Reviews( 0 )

Document information

Connected school, study & course

About the document

Uploaded On

Feb 16, 2021

Number of pages

8

Written in

Additional information

This document has been written for:

Uploaded

Feb 16, 2021

Downloads

0

Views

33