Physics > QUESTIONS & ANSWERS > Pump Performance (All)

Pump Performance

Document Content and Description Below

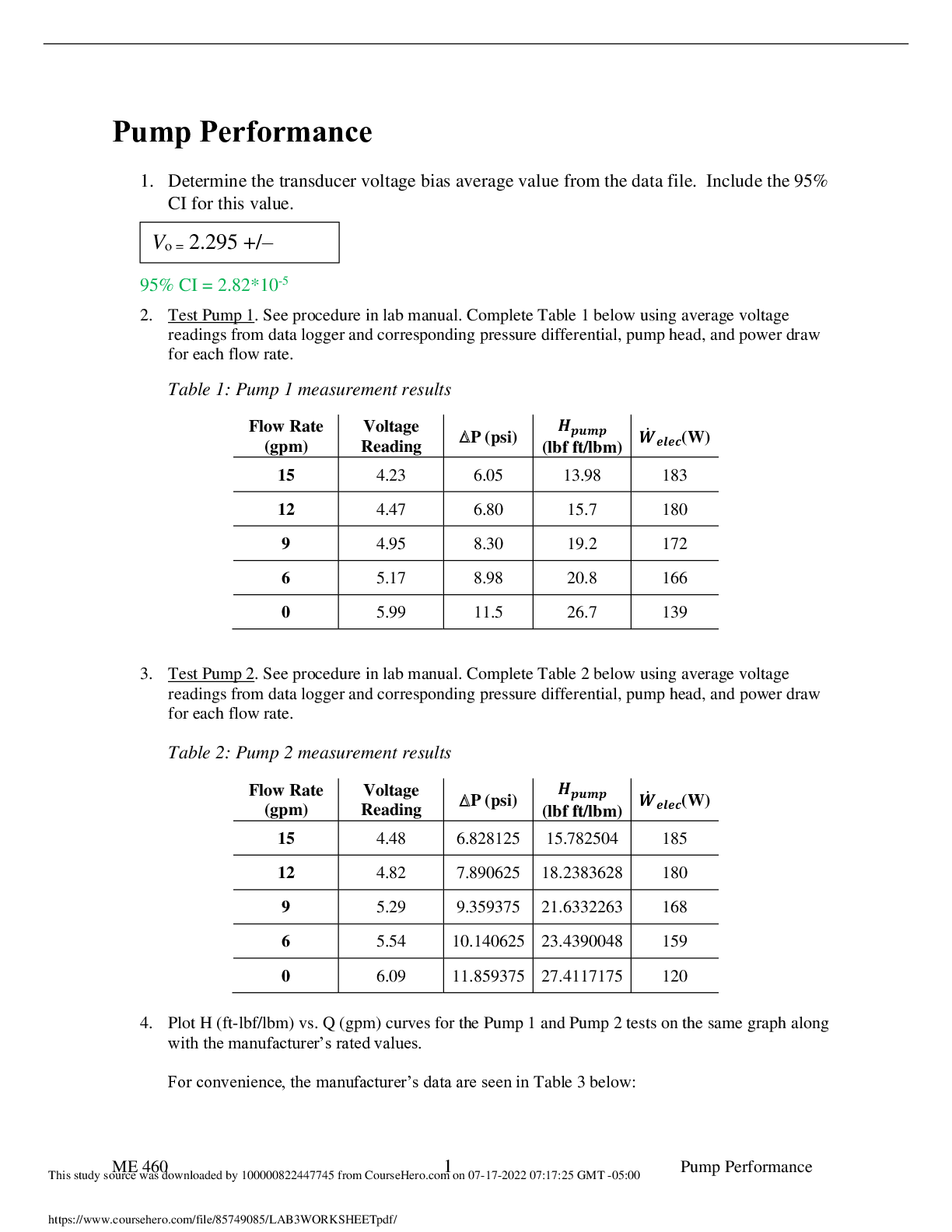

Pump Performance Pump Performance 1. Determine the transducer voltage bias average value from the data file. Include the 95% CI for this value. 95% CI = 2.82*10-5 2. Test Pump 1. See procedure in... lab manual. Complete Table 1 below using average voltage readings from data logger and corresponding pressure differential, pump head, and power draw for each flow rate. Table 1: Pump 1 measurement results Flow Rate (gpm) Voltage Reading P (psi) (lbf ????? ft/lbm) ?̇ ????(W) 15 4.23 6.05 13.98 183 12 4.47 6.80 15.7 180 9 4.95 8.30 19.2 172 6 5.17 8.98 20.8 166 0 5.99 11.5 26.7 139 3. Test Pump 2. See procedure in lab manual. Complete Table 2 below using average voltage readings from data logger and corresponding pressure differential, pump head, and power draw for each flow rate. Table 2: Pump 2 measurement results Flow Rate (gpm) Voltage Reading P (psi) (lbf ft/lbm ????? ) ?̇ ????(W) 15 4.48 6.828125 15.782504 185 12 4.82 7.890625 18.2383628 180 9 5.29 9.359375 21.6332263 168 6 5.54 10.140625 23.4390048 159 0 6.09 11.859375 27.4117175 120 4. Plot H (ft-lbf/lbm) vs. Q (gpm) curves for the Pump 1 and Pump 2 tests on the same graph along with the manufacturer’s rated values. For convenience, the manufacturer’s data are seen in Table 3 below: Vo = 2.295 +/– This study source was downloaded by 100000822447745 from CourseHero.com on 07-17-2022 07:17:25 GMT -05:00 https://www.coursehero.com/file/85749085/LAB3WORKSHEETpdf/ME 460 2 Pump Performance Table 3: Manufacturer's Data for Grundfos pumps GPM 0 2 4 6 8 10 12 14 16 18 20 Head 29.9 28.7 27.1 25 22.9 20.6 18 15.5 12.8 10.4 7.6 Figure 1 Plot showing Head Loss vs. Flow Rate Curves with error bars 5. Compare and discuss these three pump curves. As seen in Figure 1 above, all three curves follow the same inverse relationship trend, in that as flow rate increases, head loss decreases. Pumps 1 and pumps 2 both have relatively similar curves, with an almost identical slope. The manufacturer’s values however appear to have a much steeper slope. A reason for this could arise from the fact that the manufacturers’ values have more data points in its curve, thereby making its curve more precise. If there were more data points for the pumps 1 and 2 curves, those curves could possibly look more similar to the manufacturer’s curve. 6. Test Pumps 1 and 2 in Series. See procedure in lab manual. Complete Table 4 below using average voltage readings from data logger and corresponding pressure differential, pump head, and power draw for each flow rate. 5 0 10 15 20 25 30 0 4 8 12 16 Head Loss (lbf-ft/lbm) Flow Rate (GPM) Pump 1 Pump 2 Manufactuer's Data This study source was downloaded by 100000822447745 from CourseHero.com on 07-17-2022 07:17:25 GMT -05:00 https://www.coursehero.com/file/85749085/LAB3WORKSHEETpdf/ME 460 3 Pump Performance Table 4: Series pumps measurement results Flow Rate (gpm) Voltage Reading P (psi) (lbf ft/lbm ????? ) ?̇ ????(W) 16 4.74 7.64 17.7 373 15 5.09 8.73 20.2 371 12 6.52 13.2 30.5 356 9 7.45 16.1 37.2 341 6 8.25 18.6 43.0 322 0 9.79 23.4 54.1 322 7. Calculate the predicted H (ft-lbf/lbm) vs. Q (gpm) series pump curve using the results for the individual tests of Pumps 1 and 2. On the same graph, plot this predicted series curve and the curve from the actual measured results of the Pumps 1 and 2 series test. Since pumps 1 and 2 are in series, and because pumps in series operate at a constant flow rate, calculating the predicted head loss values can easily be obtained by adding the head losses measured at the same flow rates together for pumps 1 and 2. For example, Htot at 15 GPM can be calculated by adding Hpump1 at 15 GPM and Hpump2 at 15 GPM together. Figure 2 Plot showing Head Loss vs. Flow Rate Curves for pumps 1 & 2 in series with error bars 0 10 20 30 40 50 60 0 5 10 15 20 Head Loss (lbf-ft/lbm) Flow Rate (GPM) Measured Values Predicted Values This study source was downloaded by 100000822447745 from CourseHero.com on 07-17-2022 07:17:25 GMT -05:00 https://www.coursehero.com/file/85749085/LAB3WORKSHEETpdf/ME 460 4 Pump Performance 8. Compare and discuss these two curves. As seen in Figure 2 above, both curves follow the same pattern, in that head loss decreases as flow rate increases. At 0 GPM, both the predicted and measured head loss values are nearly equal, and as the flow rate increases, the predicted and measured head loss values slowly grow a little further apart from each other. Throughout the curve, the predicted head loss values are calculated to be a little higher than the measure values. The highest gap between predicted and measured head losses occurs at 15 GPM, where the predicted head loss value is 50% higher than the measured head loss value. A reason for this could be a result of experimental error from the lab. 9. Test Pumps 1 and 2 in Parallel. See procedure in lab manual. Complete Error! Reference source not found. below using average voltage readings from data logger and corresponding pressure differential, pump head, and power draw for each flow rate. Table 5: Parallel pumps measurement results Flow Rate (gpm) Voltage Reading P (psi) (lbf ft/lbm ????? ) ?̇ ????(W) 20 4.93 8.234375 19.0329053 346 15 5.25 9.234375 21.3443018 328 10 5.56 10.203125 23.5834671 309 5 5.75 10.796875 24.9558587 291 0 5.99 11.546875 26.6894061 267 *Replace with full open flow rate and delete this footnote 10. Calculate the predicted H (ft-lbf/lbm) vs. Q (gpm) parallel pump curve using the results for the individual tests of Pumps 1 and 2. On the same graph, plot this predicted parallel curve and the curve from the actual measured results of the Pumps 1 and 2 parallel tests. Since pumps 1 and 2 are in parallel, and because pumps in series operate at a constant head, calculating the predicted flow rate values have to be obtained with the quadratic formula. Polynomial curves for pumps 1 and 2 were obtained by plotting the pumps 1 and 2 data, and then using its polynomial trendline equation. Using that equation for each individual measured head loss values for pumps 1 and 2, the flow rate is calculated by using the quadratic formula. Once the flow rates are calculated, those two parallel flow rate values at pumps 1 and 2 are added together. [Show More]

Last updated: 1 year ago

Preview 1 out of 7 pages

Reviews( 0 )

Document information

Connected school, study & course

About the document

Uploaded On

Feb 06, 2023

Number of pages

7

Written in

Additional information

This document has been written for:

Uploaded

Feb 06, 2023

Downloads

0

Views

48

.png)