Engineering > Lab Report > Heat Treatment Lab University of Guelph ENGG 2120 (All)

Heat Treatment Lab University of Guelph ENGG 2120

Document Content and Description Below

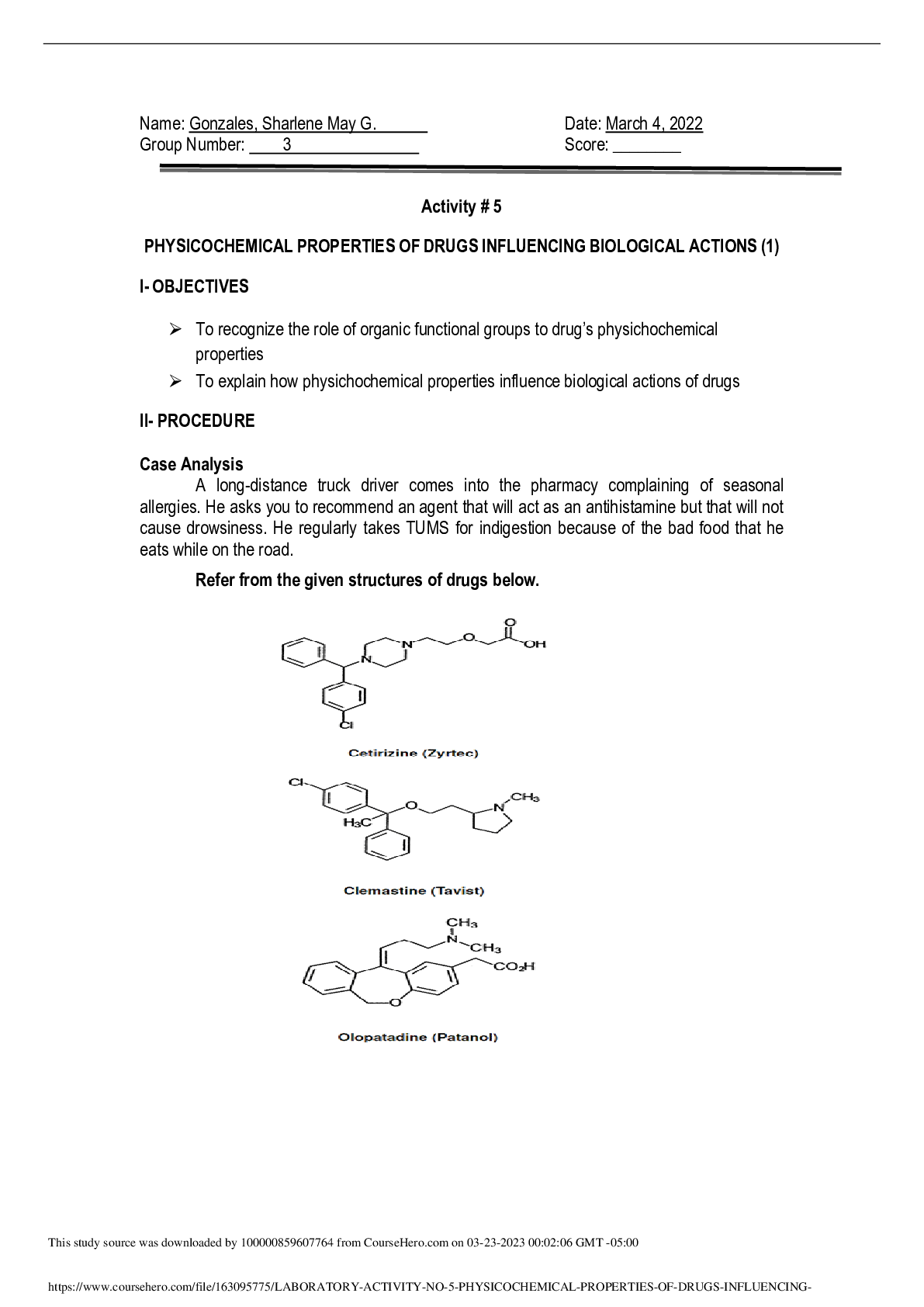

University of Guelph School of Engineering ENGG*2120 Heat Treatment of Steels Summary Heat treatment of a material is analyzed through experimentation to determine the effects that it has on the... microstructure as well as hardening of steels. Heat treating alters the amount of carbides in a material, altering its hardness. In this lab AISI 1045 and 4140 steels undergo various heat treatment processes. Each type of material will be heated to 800 degrees Celsius in an oven. They will then be placed in ether water for 30 seconds, oil for 3 minutes or cool down with air for 20 minutes, then reheated for 20 minutes in a 400 degrees Celsius oven, and then once more. After every test the hardness of the material is recorded. By comparing the discovered hardness's before and after each treatment the results of their effects can be found. The hardest material and treatment were the AISI 4140 water quenched steel although it is also the most brittle. Whereas, the softest treatment is AISI 1045 steel air quenched for 20 minutes it is also the most ductile. The shorter the ii heat treatment means the harder the outer layer of metal will be. Tempering also increases the ductility well decreasing the hardness. AISI 1045 water quenched decreased from 25 HRC to 97 HRB after being tempered twice. 3 Table of Contents i. Title........................................................................................................................................... i ii. Summary ................................................................................................................................... i 1.0 Introduction............................................................................................................................... 1 2.0 Experimental Apparatus and Procedures................................................................................. 1 3.1 Iron-Carbon Phase Diagram ................................................................................................ 2 Figure 1: Iron-Carbon Phase Diagram ................................................................................................2 3.2 Hardness Results................................................................................................................... 3 Figure 2: 1045 Steel Hardness Results .................................................................................................3 Figure 3: 4140 Steel Hardness Results .................................................................................................3 3.3 Effects of Heat Treatment...................................................................................................... 4 4.0 Discussion................................................................................................................................. 5 6.0 References............................................................................................................................... 10 [Show More]

Last updated: 1 year ago

Preview 1 out of 13 pages

Reviews( 0 )

Document information

Connected school, study & course

About the document

Uploaded On

Nov 17, 2022

Number of pages

13

Written in

Additional information

This document has been written for:

Uploaded

Nov 17, 2022

Downloads

0

Views

57

.png)

(1).png)

.png)

.png)