Operations Management > QUESTIONS & ANSWERS > University of Houston, Downtown - MGT 3332. Chapter16 Solutions. All Answers Provided. See Questions (All)

University of Houston, Downtown - MGT 3332. Chapter16 Solutions. All Answers Provided. See Questions in the Description.

Document Content and Description Below

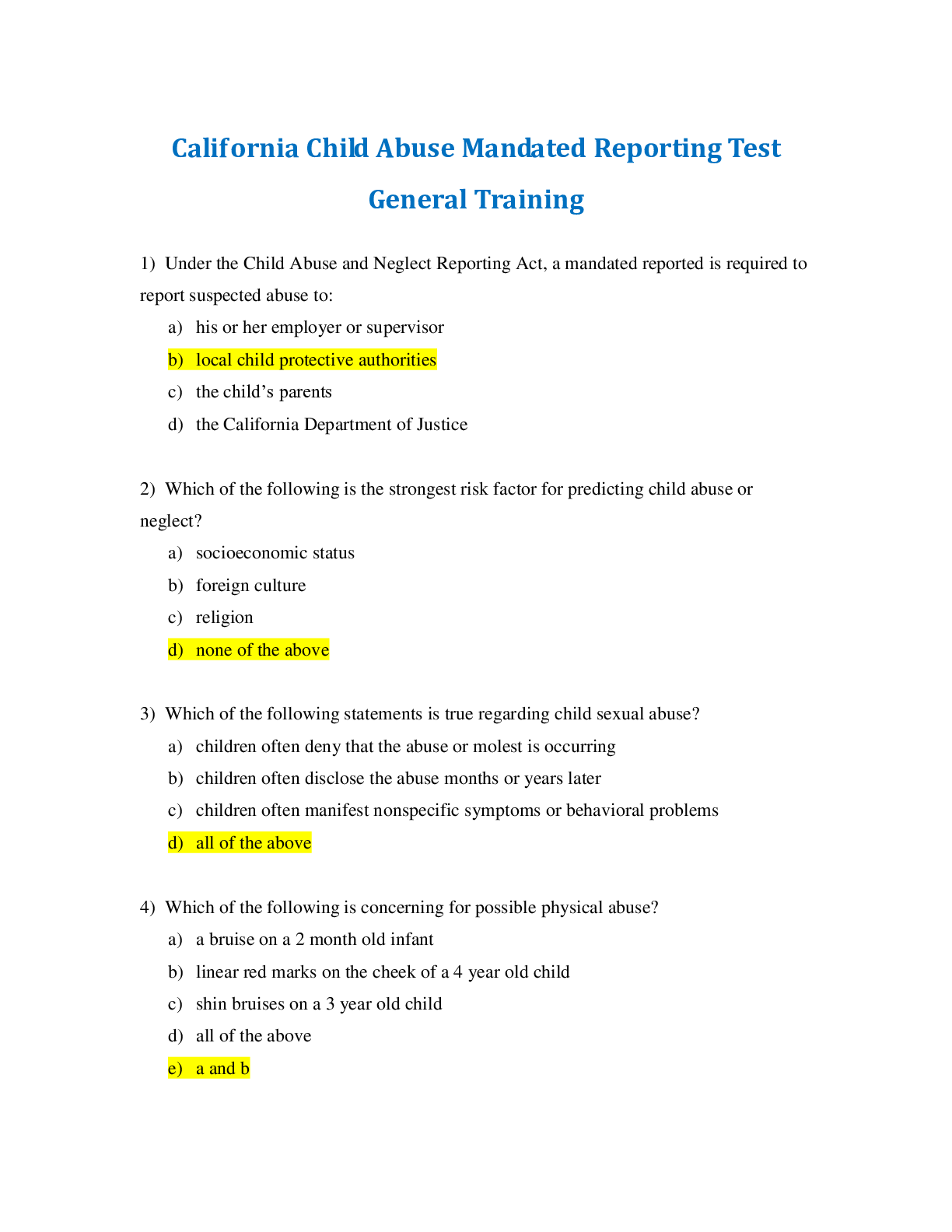

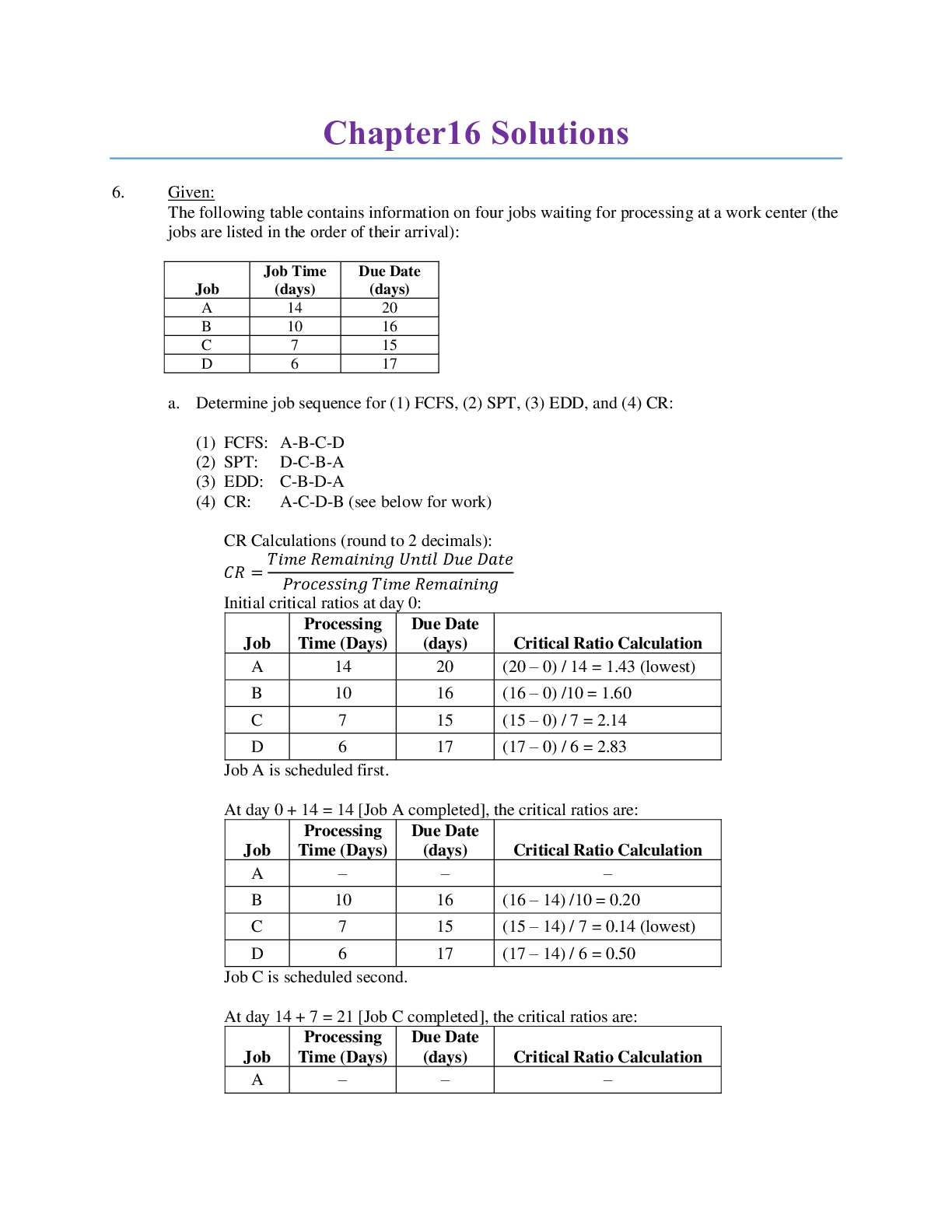

Chapter16 Solutions 6. Given: The following table contains information on four jobs waiting for processing at a work center (the jobs are listed in the order of their arrival): a. Determine job... sequence for (1) FCFS, (2) SPT, (3) EDD, and (4) CR: At day 21 + 6 = 27 [Job D completed], only Job B remains. Job B is scheduled fourth and will be completed on day 27 + 10 = 37. b. For each of the methods above, determine the (1) average flow time, (2) average tardiness, and (3) average number of jobs at the work center. Job flow time = Time it takes from when job arrives (day 0 in this problem) until it is complete. Tardiness = Flow time – Due date (0 if negative). Average number of jobs = Total flow time / Makespan. Makespan = Total of job times. c. SPT is superior because it provides the lowest value for each of the three measures. 7. Given: The following table contains information on five jobs waiting for processing at a work center (the jobs are listed in the order of their arrival): Job flow time = Time it takes from when job arrives (hour 0 in this problem) until it is complete. Tardiness = Flow time – Due date (0 if negative). Average number of jobs = Total flow time / Makespan. Makespan = Total of job times. FCFS Sequence: a-b-c-d-e Average job flow time = Total job flow time / Number of jobs = 87 / 5 = 17.40 hours. Average job tardiness = Total job tardiness / Number of jobs = 26 / 5 = 5.20 hours. Average number of jobs = Total flow time / Makespan = 87 / 32 = 2.72 jobs. SPT Sequence: c-b-a-e-d Average job flow time = Total job flow time / Number of jobs = 74 / 5 = 14.80 hours. Average job tardiness = Total job tardiness / Number of jobs = 27 / 5 = 5.40 hours. Average number of jobs = Total flow time / Makespan = 74 / 32 = 2.31 jobs. EDD Sequence: a-b-c-e-d Average job flow time = Total job flow time / Number of jobs = 84 / 5 = 16.80 hours. Average job tardiness = Total job tardiness / Number of jobs = 23 / 5 = 4.60 hours. Average number of jobs = Total flow time / Makespan = 84 / 32 = 2.63 jobs. Critical Ratio: CR Calculations (round to 2 decimals): CR=(Time Remaining Until Due Date)/(Processing Time Remaining) Initial critical ratios at hour 0: Job a is scheduled first. Job b is scheduled second. At hour 7 + 4 = 11 [Job b completed], the critical ratios are: Jobs c & e are tied for lowest. We will break the tie arbitrarily and schedule Job c third. The alternate solution scheduling Job e third is shown below. Alternate Critical Ratio Solution: Critical Ratio: CR Calculations (round to 2 decimals): 9. Given: A wholesale grocery distribution system uses a two-step process to fill orders. Tomorrow’s work will consist of filling the seven orders shown below. Determine a job sequence that will minimize the time required to fill the orders: We will use Johnson’s rule to sequence the jobs. The Johnson’s rule steps from the text are shown below: 1. Select the job with the shortest time. If the shortest time is at the first work center, schedule that job first; if the time is at the second work center, schedule the job last. Break ties arbitrarily. 2. Eliminate the job and its time from further consideration. 3. Repeat steps 1 and 2, working toward the center of the sequence, until all jobs have been scheduled. (a) Order C has the shortest time (0.80). Because the time is at Step 2, schedule Order C last (7th). Eliminate Order C from further consideration. (b) Order B has the shortest time (0.90). Because the time is at Step 1, schedule Order B first (1st) . Eliminate Order B from further consideration. (c) Order A has the shortest time (1.20). Because the time is at Step 1, schedule Order A toward the beginning of the sequence (2nd). Eliminate Order A from further consideration. (d) Order G has the shortest time (1.30). Because the time is at Step 1, schedule Order G toward the beginning of the sequence (3rd). Eliminate Order G from further consideration. (e) Order D has the shortest time (1.50). Because the time is at Step 2, schedule Order D toward the end of the sequence (6th). Eliminate Order D from further consideration. (f) Order E has the shortest time (1.60). Because the time is at Step 1, schedule Order E toward the beginning of the sequence (4th). Eliminate Order E from further consideration. (g) Order F is the only order remaining. Schedule Order F 5th. Eliminate Order F from further consideration. The final schedule is shown below: 10. Given: The times required to complete each of 8 jobs in a two-machine flow shop are shown in the table below. Each job must follow the same sequence, beginning with Machine A and moving to Machine B. a. Determine a sequence that will minimize makespan time: We will use Johnson’s rule to sequence the jobs. The Johnson’s rule steps from the text are shown below: 1. Select the job with the shortest time. If the shortest time is at the first work center, schedule that job first; if the time is at the second work center, schedule the job last. Break ties arbitrarily. 2. Eliminate the job and its time from further consideration. 3. Repeat steps 1 and 2, working toward the center of the sequence, until all jobs have been scheduled. (a) Job e has the shortest time (2). Because the time is at Machine A, schedule Job e first (1st). Eliminate Job e from further consideration. (b) Job b has the shortest time (3). Because the time is at Machine A, schedule Job b toward the beginning of the sequence (2nd). Eliminate Job b from further consideration. (c) Job f has the shortest time (4). Because the time is at Machine B, schedule Job f last (8th). Eliminate Job f from further consideration. (d) Job a has the shortest time (5). Because the time is at Machine B, schedule Job a toward the end of the sequence (7th). Eliminate Job a from further consideration. (e) Job c has the shortest time (6). Because the time is at Machine B, schedule Job c toward the end of the sequence (6th). Eliminate Job c from further consideration. (f) Job d has the shortest time (7). Because the time is at Machine B, schedule Job d toward the end of the sequence (5th). Eliminate Job d from further consideration. (g) Job h has the shortest time (11). Because the time is at Machine B, schedule Job h toward the end of the sequence (4th). Eliminate Job h from further consideration. (h) Job g is the only job remaining. Schedule Job g 3rd. Eliminate Job g from further consideration. The final schedule is shown below: b. Construct a chart of the resulting sequence, and Machine B’s idle time: c. Determine how much Machine B’s idle time would be reduced by splitting the last two jobs After splitting, we obtain the following Gantt chart: After splitting, Machine B’s idle time is = 2 + 1 + 5.5 + 3.5 + 4 = 16 hours, and the new makespan = 90. Machine B’s idle time would be reduced by 2 hours (18 – 16). 11. Given: Given the operation times provided: a. Develop a job sequence that minimizes idle time at the two work centers. We will use Johnson’s rule to sequence the jobs. The Johnson’s rule steps from the text are shown below: 1. Select the job with the shortest time. If the shortest time is at the first work center, schedule that job first; if the time is at the second work center, schedule the job last. Break ties arbitrarily. 2. Eliminate the job and its time from further consideration. 3. Repeat steps 1 and 2, working toward the center of the sequence, until all jobs have been scheduled. (a) Job D has the shortest time (12). Because the time is at Center 2, schedule Job D last (6th). Eliminate Job D from further consideration. (b) Job B has the shortest time (16). Because the time is at Center 1, schedule Job B first (1st). Eliminate Job B from further consideration. c) Job A has the shortest time (20). Because the time is at Center 1, schedule Job A toward the beginning of the sequence (2nd). Eliminate Job A from further consideration. (d) Job F has the shortest time (24). Because the time is at Center 2, schedule Job F toward the end of the sequence (5th). Eliminate Job F from further consideration. (e) Job E has the shortest time (28). Because the time is at Center 2, schedule Job E toward the end of the sequence (4th). Eliminate Job E from further consideration. (f) Job C is the only job remaining. Schedule Job C 3rd. Eliminate Job C from further consideration. The final schedule is shown below: b. Construct a chart of the activities at the two centers, and determine each one’s idle time: Center 1: 0 minutes of idle time. Center 2: 16 + 6 + 34 = 56 minutes of idle time. [Show More]

Last updated: 1 year ago

Preview 1 out of 19 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Add to cartInstant download

We Accept:

Reviews( 0 )

$13.00

Document information

Connected school, study & course

About the document

Uploaded On

Feb 17, 2021

Number of pages

19

Written in

Additional information

This document has been written for:

Uploaded

Feb 17, 2021

Downloads

0

Views

145